The Science Behind Automotive Braking Systems

Automotive braking systems are a critical aspect of vehicle safety and control, often taken for granted until their immediate need arises. Understanding the underlying science and engineering principles that allow a moving vehicle to safely come to a halt is fundamental for appreciating modern automotive design. This intricate network of components converts kinetic energy into thermal energy through friction, enabling precise control over speed and ensuring the safety of occupants and others on the road. From the moment a driver applies pressure to the brake pedal, a complex series of events unfolds, demonstrating remarkable innovation in mechanical and hydraulic principles.

Fundamental Principles of Automotive Safety and Braking Technology

At its core, an automotive braking system operates on the principle of friction, a force that opposes motion. When brakes are applied, components within the system create friction against the rotating wheels, converting the vehicle’s kinetic energy (energy of motion) into thermal energy (heat). This energy transformation is essential for slowing down or stopping the vehicle. The efficiency of this conversion directly impacts the stopping distance and overall vehicle safety. Modern braking technology has evolved significantly, integrating advanced materials and electronic controls to maximize this frictional force predictably and reliably under various driving conditions, thereby enhancing the overall safety of mobility.

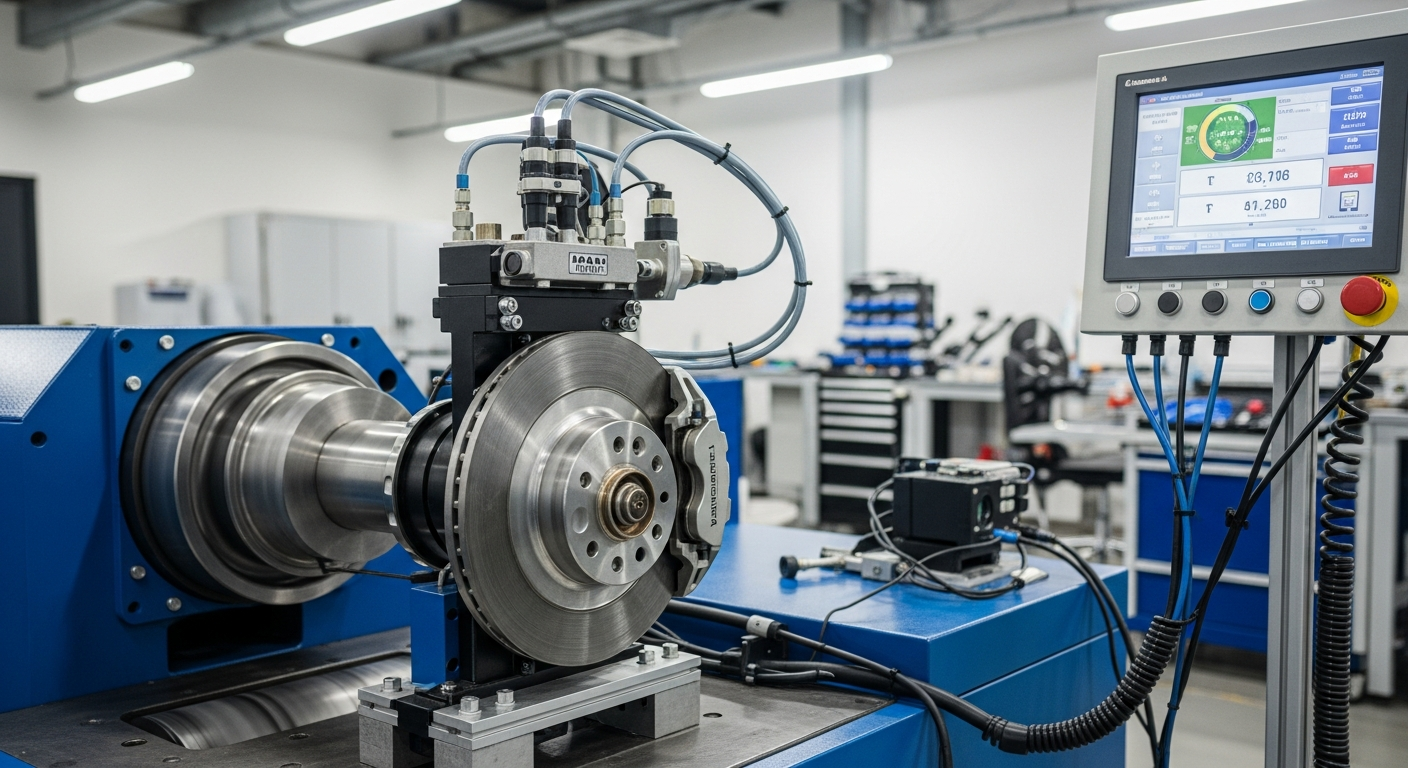

Key Components in Braking System Engineering and Design

The effective operation of a braking system relies on a carefully engineered series of components. The process begins with the driver pressing the brake pedal, which actuates a master cylinder. This cylinder converts the mechanical force into hydraulic pressure, pushing brake fluid through a network of brake lines to the calipers or wheel cylinders. For disc brakes, the calipers clamp brake pads onto a rotating disc (rotor) attached to the wheel. In drum brakes, wheel cylinders push brake shoes against the inside of a spinning drum. The friction generated between the pads and rotors, or shoes and drums, is what slows the rotation of the wheels. The precise design and material choice for these components are critical for consistent performance and durability in automotive applications.

Enhancing Driving Performance and Efficiency with Advanced Braking

Innovation in braking systems extends beyond basic friction. Modern vehicles incorporate advanced technologies to improve driving performance and efficiency. Anti-lock Braking Systems (ABS) prevent the wheels from locking up during hard braking, allowing the driver to maintain steering control. Electronic Brakeforce Distribution (EBD) optimizes the braking force applied to each wheel, depending on factors like load distribution and road conditions, further enhancing stability. Traction control systems often work in conjunction with braking components to prevent wheel spin during acceleration. These integrated systems represent significant advancements in automotive engineering, ensuring more controlled stops and contributing to a safer transportation experience, even when navigating challenging road surfaces.

Braking Systems in Electric and Hybrid Mobility

Electric (EV) and hybrid vehicles introduce a distinct approach to braking through regenerative braking. Unlike conventional friction brakes that solely dissipate kinetic energy as heat, regenerative braking systems capture a portion of this energy and convert it back into electricity. This electricity is then stored in the vehicle’s battery, effectively extending the driving range and improving energy efficiency. While these vehicles still incorporate traditional friction brakes for rapid deceleration or emergency stops, regenerative braking significantly reduces wear on brake pads and rotors and contributes to the overall efficiency of electric motors. This blend of technologies represents a key aspect of sustainable mobility and future automotive design.

Maintaining Braking Systems for Reliable Road Travel

Regular maintenance of a vehicle’s braking system is paramount for ensuring reliable and safe road travel. This includes routine inspection of brake pads, rotors, and drums for wear, as well as checking the brake fluid level and condition. Brake fluid is hygroscopic, meaning it absorbs moisture over time, which can reduce its boiling point and compromise braking performance. Worn brake components can lead to longer stopping distances, reduced control, and potential safety hazards. Adhering to manufacturer-recommended service schedules for brake checks and fluid changes helps maintain the system’s integrity, ensuring that the vehicle’s stopping capabilities remain optimal for confident driving and overall transportation safety.

In conclusion, automotive braking systems are a testament to sophisticated engineering, blending mechanical principles with advanced technology to ensure vehicle safety and control. From the fundamental physics of friction to the innovative energy recovery in electric vehicles, each component and system plays a vital role in the overall performance of a vehicle. Understanding these intricate mechanisms highlights the continuous pursuit of safer and more efficient mobility solutions for drivers and passengers worldwide.