The Mechanics of Hybrid Propulsion Systems

Hybrid propulsion systems represent a significant evolution in automotive technology, blending the efficiency of electric motors with the power of internal combustion engines. These sophisticated systems are designed to optimize fuel consumption and reduce emissions, offering a compelling solution for sustainable mobility. Understanding their fundamental mechanics reveals the intricate engineering behind modern vehicles.

Understanding Hybrid Powertrain Designs

Hybrid vehicles integrate multiple power sources, primarily an internal combustion engine (ICE) and an electric motor, to propel the vehicle. The way these components interact defines the type of hybrid powertrain design. Full hybrids, for instance, can operate on electric power alone, gasoline power alone, or a combination of both. Parallel hybrids allow both the electric motor and the ICE to power the wheels simultaneously, offering direct power delivery and often using the electric motor to assist acceleration. Series hybrids, on the other hand, use the ICE primarily as a generator to charge the battery or power the electric motor, meaning the electric motor is the sole source of propulsion for the wheels. Series-parallel, or power-split, hybrids combine aspects of both, offering the flexibility to operate in various modes for optimal efficiency across different driving conditions. This adaptable design ensures that the vehicle can switch seamlessly between power sources to maximize fuel economy and performance, making them a cornerstone of contemporary automotive innovation.

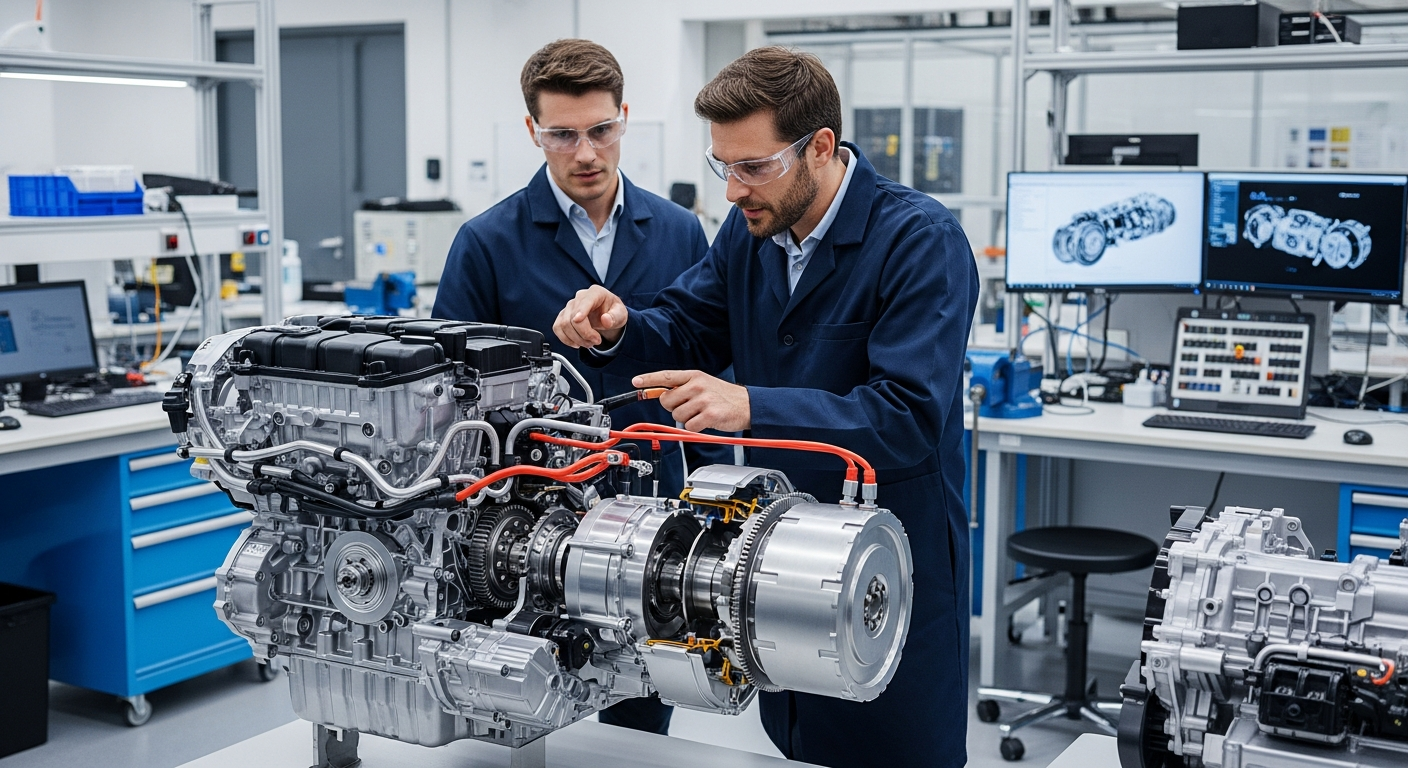

Core Components and Electric Integration

At the heart of any hybrid system are several key components that work in harmony. These include the internal combustion engine, one or more electric motors, a battery pack for storing electrical energy, a power control unit (PCU), and a transmission system. The electric motor converts electrical energy into mechanical energy to drive the wheels, while the battery stores energy, often a high-voltage lithium-ion or nickel-metal hydride unit. The PCU is a critical piece of technology, acting as the brain of the hybrid system. It manages the flow of electrical power between the battery, electric motor, and generator, converting direct current (DC) from the battery to alternating current (AC) for the motor and vice-versa. This sophisticated integration allows the system to intelligently decide when to use electric power, gasoline power, or a combination, optimizing efficiency and performance. Regenerative braking is another crucial aspect, where the electric motor acts as a generator during deceleration, converting kinetic energy back into electricity to recharge the battery, further enhancing the overall efficiency of these vehicles.

Efficiency, Performance, and Sustainability Aspects

The primary advantages of hybrid propulsion systems lie in their enhanced fuel efficiency, reduced emissions, and often improved driving performance compared to conventional vehicles. By strategically combining power sources, hybrids can achieve higher miles per gallon, especially in urban driving cycles where frequent stopping and starting allow the electric motor to take over or assist. The ability to shut off the gasoline engine at idle or low speeds, known as engine stop-start technology, significantly conserves fuel. Furthermore, the instantaneous torque provided by electric motors can offer brisk acceleration, contributing to a responsive driving experience. From a sustainability perspective, hybrid vehicles play a vital role in reducing the carbon footprint of transport. By consuming less fossil fuel and emitting fewer greenhouse gases and pollutants, they contribute to cleaner air and a more sustainable future for mobility. These environmental benefits, coupled with practical performance, underscore the growing appeal of hybrid technology worldwide.

Advanced Hybrid Technologies and Future Outlook

The landscape of hybrid technology continues to evolve with significant innovations. Plug-in Hybrid Electric Vehicles (PHEVs) represent a notable advancement, featuring larger battery packs that can be charged from an external power source, offering a greater electric-only range than traditional hybrids. Mild hybrids, another development, use a smaller electric motor to assist the ICE, primarily for functions like engine stop-start and torque assist, providing a cost-effective way to improve efficiency. The integration of advanced software and connectivity features further optimizes hybrid systems, allowing for predictive energy management based on navigation data and real-time traffic conditions. Looking ahead, hybrid technology is expected to continue its integration with other emerging automotive trends, such as autonomous driving systems. The intelligent management of power sources in hybrids aligns well with the precision and efficiency required for autonomous operation, suggesting a future where highly efficient, connected, and potentially self-driving hybrid vehicles become more prevalent, pushing the boundaries of vehicle design and functionality.

Manufacturing Processes and Safety Considerations

The manufacturing of hybrid vehicles involves complex processes due to the integration of multiple sophisticated systems. Producing high-voltage battery packs, electric motors, and power control units requires specialized facilities and expertise, distinct from traditional internal combustion engine vehicle assembly. The design and manufacturing processes must account for the weight distribution of battery packs and the routing of high-voltage cabling. Safety is a paramount concern in hybrid vehicle design, particularly regarding the high-voltage electrical components. Manufacturers implement rigorous safety protocols, including robust insulation, shielding, and automatic shutdown systems, to protect occupants and service technicians from electrical hazards. Crash tests and structural reinforcements are also adapted to ensure the integrity of battery packs and other critical components during an impact. These comprehensive safety measures are integral to the development and deployment of hybrid vehicles, ensuring reliability and consumer confidence in this advanced form of transport.

Hybrid propulsion systems represent a crucial step in the evolution of automotive engineering, offering a balance of efficiency, performance, and environmental responsibility. Through continuous innovation in powertrain design, component integration, and advanced technologies, hybrids are setting new standards for sustainable mobility. Their sophisticated mechanics underscore a commitment to developing vehicles that meet the demands of modern driving while contributing positively to global sustainability efforts, solidifying their role in the future of transport.